Case Study

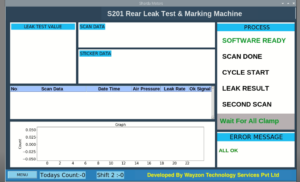

IoT-Based Data Acquisition and Traceability System for Leak Test SPM

Client Overview

Sharda Motors Industries Ltd is a leading manufacturer of automotive components, specializing in exhaust systems, suspension systems, and body structures. To enhance their quality control and traceability processes, they required an advanced data acquisition and traceability solution for their Leak Test Special Purpose Machines (SPMs).

Project Summary

The IoT-based Data Acquisition and Traceability System was deployed at Sharda Motors Industries Ltd’s Pune Plant 1 & 2 and Nashik Plant 1 & 2. The system integrates with leak test machines (such as ATEQ) and marking machines (such as Marksman or Automator) to collect, store, and manage leak test data efficiently.

Challenges Faced

-

Lack of real-time traceability of leak test results.

-

Manual data logging errors leading to inconsistencies in quality reports.

-

Inability to link test results with unique part identification.

-

Repeated leak testing causing inefficiencies in production.

-

Delayed reporting affecting production and quality control decision-making.

Solution Implemented

The IoT-based Data Acquisition and Traceability System was implemented to overcome these challenges by enabling:

1. Automated Data Collection

-

Captures leak test data in LPM (Liters Per Minute) directly from leak test machines like ATEQ.

-

Links test data with unique part identification by integrating with Marksman and Automator marking machines.

-

Provides unique QR codes with details including leak value, date, time, shift, company logo, ensuring easy traceability.

-

Barcode printers are used to print QR code labels, which are then pasted onto the respective parts.

-

Scanners are provided to ensure Poka-Yoke validation, confirming that the QR code is affixed to the correct part before moving forward.

2. Cloud-Based Data Traceability

-

All leak test data and generated QR codes are stored securely on the cloud.

-

Data can be accessed anytime, from anywhere, via a dedicated URL.

-

Enables real-time tracking of production, quality, and maintenance data.

3. Automated Reports & Notifications

-

Daily production analysis reports are automatically emailed to registered recipients.

-

Quality, production, and maintenance reports are accessible online and shared via email or mobile notifications.

-

Maintenance alarms generated by the PLC are sent in real-time to the concerned department, reducing downtime and improving efficiency.

Key Business Impact

1. Increased Production Efficiency

-

At Lumax, the implementation of the IoT system resulted in a 25% increase in production.

2. Reduction in Repeated Leak Testing

-

At Sharda Motors, repeated leak testing was reduced by 30%, improving overall efficiency and reducing waste. Production is increased by 20% as real time data is shown on cloud system for monitoring purpose. Machine ideal state is reduced from 2.3 hrs to 15 minutes .

3. Enhanced Traceability & Compliance

-

Each part undergoes complete traceability, ensuring adherence to quality standards and industry regulations.

4. Real-Time Data Access & Decision Making

-

With cloud-based storage, management teams can access reports anytime and make data-driven decisions.

-

Mobile and email notifications ensure instant alerts for any anomalies in production or maintenance requirements.

Conclusion

The IoT-based Data Acquisition and Traceability System has significantly improved operational efficiency, traceability, and production quality at Sharda Motors Industries Ltd. By leveraging real-time data collection, cloud storage, and automated reporting, the company has achieved greater accuracy in leak testing while reducing downtime and optimizing production workflows.

This successful implementation highlights the power of IoT in industrial automation and serves as a model for other automotive manufacturing companies looking to improve quality control and production efficiency through smart data acquisition and traceability solutions.

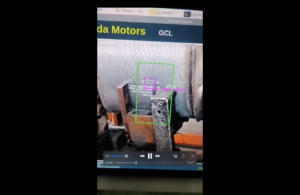

Vision-Based Quality Inspection and Traceability System

Client Overview

Sharda Motors Industries Ltd is a leading automotive components manufacturer, known for its high standards in quality control and production efficiency. To enhance process automation and traceability, the company required an advanced vision-based system for ensuring circlip presence verification during assembly.

Project Summary

The Vision-Based Quality Inspection and Traceability System was implemented at Sharda Motors Industries Ltd to ensure accurate circlip pressing during production. This system integrates with machine vision technology and IoT-based data acquisition to enhance precision, reduce errors, and improve traceability.

Challenges Faced

-

Manual inspection inefficiencies leading to incorrect circlip placement.

-

Production delays due to idle machine time caused by rework.

-

Lack of traceability of individual parts in the assembly line.

-

Quality inconsistencies affecting compliance with industry standards.

Solution Implemented

The Vision-Based Quality Inspection and Traceability System was deployed to address these challenges by enabling:

1. Automated Circlip Presence Detection

-

A vision system detects whether the circlip is properly placed on the part.

-

If the circlip is detected, the system sends a forward command to the cylinder, allowing the circlip to be clipped onto the part.

-

If the circlip is missing, the system prevents further machine operation, ensuring quality compliance.

2. QR Code Generation and Scanning for Traceability

-

Once the circlip is successfully clipped, a unique QR code is generated containing:

-

Unique ID

-

Date & Time

-

Part Details

-

Vendor Details

-

Shift Information

-

Production Count

-

-

The QR code is printed and pasted on the part to ensure traceability.

-

Before the part is unclamped, the QR code is scanned to confirm all details are correctly registered in the system.

-

Once validated, the machine releases the part and is ready for the next cycle.

3. Data Acquisition and Cloud-Based Traceability

-

All inspection data, QR codes, and production logs are stored securely on the cloud.

-

Data is accessible in real time via a dedicated URL for production monitoring.

-

Daily production analysis reports are emailed to registered recipients.

-

Quality reports, production reports, and maintenance alerts are shared via email and mobile notifications.

Key Business Impact

1. Increased Production Efficiency

-

Machine idle time was reduced by 1 hour and 50 minutes, leading to a significant boost in production output.

2. Reduction in Rework & Quality Issues

-

The vision-based system eliminated manual inspection errors, ensuring 100% accurate circlip placement.

3. Enhanced Traceability & Compliance

-

Each part is now uniquely identified with a QR code, ensuring full traceability throughout the supply chain.

4. Real-Time Data Access & Decision Making

-

Management teams can access reports anytime from any location, enabling data-driven decisions.

-

Automated alerts improve response time to production or maintenance issues.

Conclusion

The Vision-Based Quality Inspection and Traceability System at Sharda Motors Industries Ltd has significantly improved production efficiency, traceability, and quality assurance. By leveraging machine vision technology, IoT, and cloud-based data management, Sharda Motors has successfully optimized machine uptime, reduced errors, and enhanced production workflows.

This successful implementation highlights how vision-based automation can revolutionize quality control in automotive manufacturing by eliminating manual errors and increasing process efficiency.

Vision-Based Arrow Direction Detection on Muffler for Automated Welding

🏭 Industry

Automotive Manufacturing – Exhaust / Muffler Welding Line

🧩 Problem Statement

In the muffler welding process, correct orientation of the muffler is critical.

Each muffler has a directional arrow marking, and welding must start only if the arrow direction is correct.

Earlier, this verification was:

- Manual

- Error-prone

- Causing incorrect welds and rework

The client required an automated, reliable, and PLC-integrated vision solution to ensure zero welding on wrongly oriented parts.

🎯 Project Objective

- Detect arrow marking on the muffler using a camera

- Identify arrow direction (Left / Right / Correct orientation)

- Send OK / NOT OK signal to PLC

- Allow welding operation only when orientation is correct

🛠️ Solution Overview

We implemented a Vision-Based Arrow Detection System with real-time PLC communication.

System Flow:

- Camera captures muffler image before welding

- Vision algorithm detects arrow marking

- Arrow direction is calculated

- If direction matches reference:

- PLC receives OK signal

- Welding operation starts

- If direction is wrong:

- PLC blocks welding

- Operator intervention required

🧠 Technical Approach

- Edge-based arrow detection

- Direction vector analysis

- ROI-based processing for high speed

- Noise-resistant logic suitable for welding environment

Key Highlights:

- Works under industrial lighting

- Robust against dust and surface reflections

- Fast decision-making suitable for cycle-time constraints

🔌 System Architecture

- Industrial Camera mounted near welding station

- Vision Processing System (Industrial PC / Jetson)

- PLC Interface via Digital I/O / Ethernet

- Welding Machine Interlock

📊 Results & Benefits

✅ 100% prevention of wrong-orientation welding

✅ Zero manual inspection required

✅ Improved weld quality and consistency

✅ Reduced rework and scrap

✅ Seamless PLC integration

✅ Industry-ready and scalable solution

🏁 Conclusion

This project demonstrates how Vision + PLC integration can eliminate human error and enable fully automated, decision-driven welding operations.

The solution is production-proven, scalable, and adaptable to other orientation or marking-based inspection tasks.